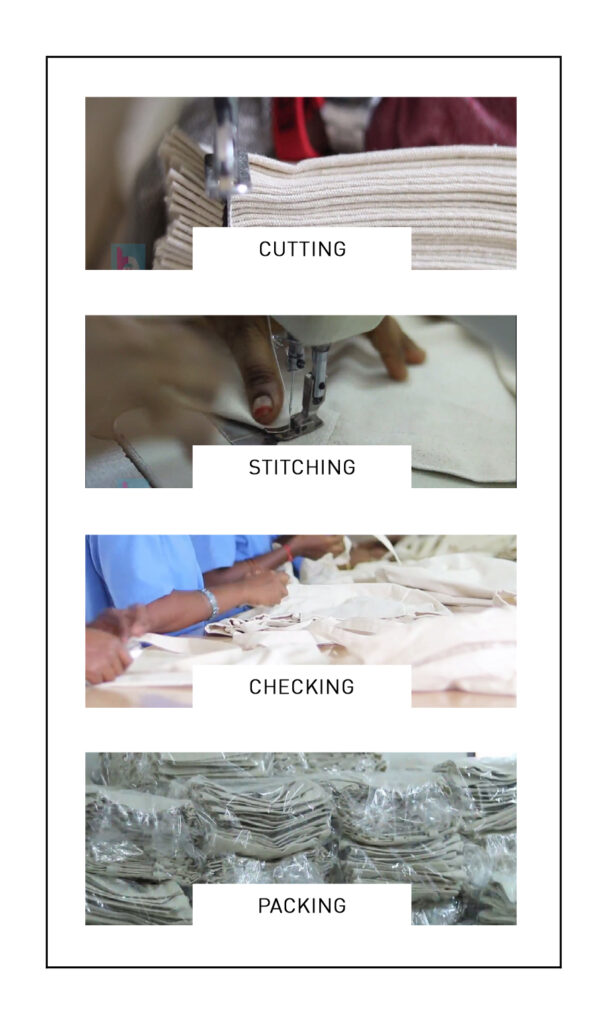

Bag Making Process

CUTTING

Cutting of the fabric is a process where specific shapes and sizes required in the production are separated from the fabric. Precision is the key factor in this process. Cutting is done both manually (using scissors) and automatically (using electric cutting machines), depending on the volume of fabric or the quality of the fabric. We make sure the pieces of fabric required for the stitching process are of the exact shape that is needed.

STITCHING

It becomes very important to ensure the stitching quality in the case of jute products. We have skilled and experienced craftsmen who have inherited these skills from their families. There are 3 kinds of stitching: inter-looping, intra-looping, and interlacing. We ensure that all the parameters of stitching quality are up to the mark.

CHECKING

Quality Check or QC is of the primary importance to our production process. All the parameters of stitching quality - stitch size, stitch length, width, depth, tension, sequence, elongation, elasticity, resilience, fabric distortion, yarn severance, and abrasive strength - are met without fail.

PACKING

We understand the importance of quality packaging. At Eskay, we keep our packages as lightweight as possible, as this solves a number of transportation problems. Also, we make sure our packaging is airtight and watertight because we know that jute is vulnerable to damage.